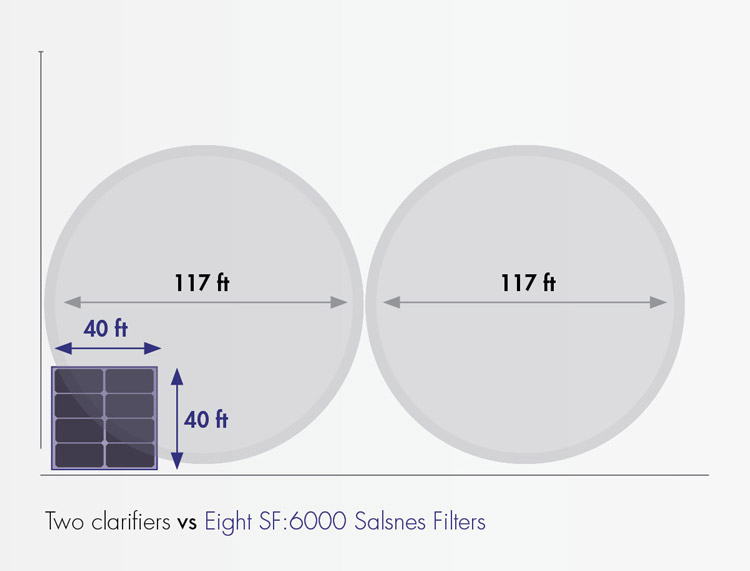

Compact footprint

A Salsnes Filter system will typically use only 1/10th the land requirements of conventional primary wastewater treatment systems, making it ideal for those areas where land is expensive or unavailable.

Ease demand on downstream processes

When one step of the treatment process is overloaded, it can negatively affect the whole treatment process. A Salsnes Filter system can reduce loadings to ease demand and increase capacity of secondary treatment processes such as:

- oxidation ditches

- sequencing batch reactors

- biological aerated filters

- dissolved air flotation

- moving bed bio reactors

- membrane bio reactors

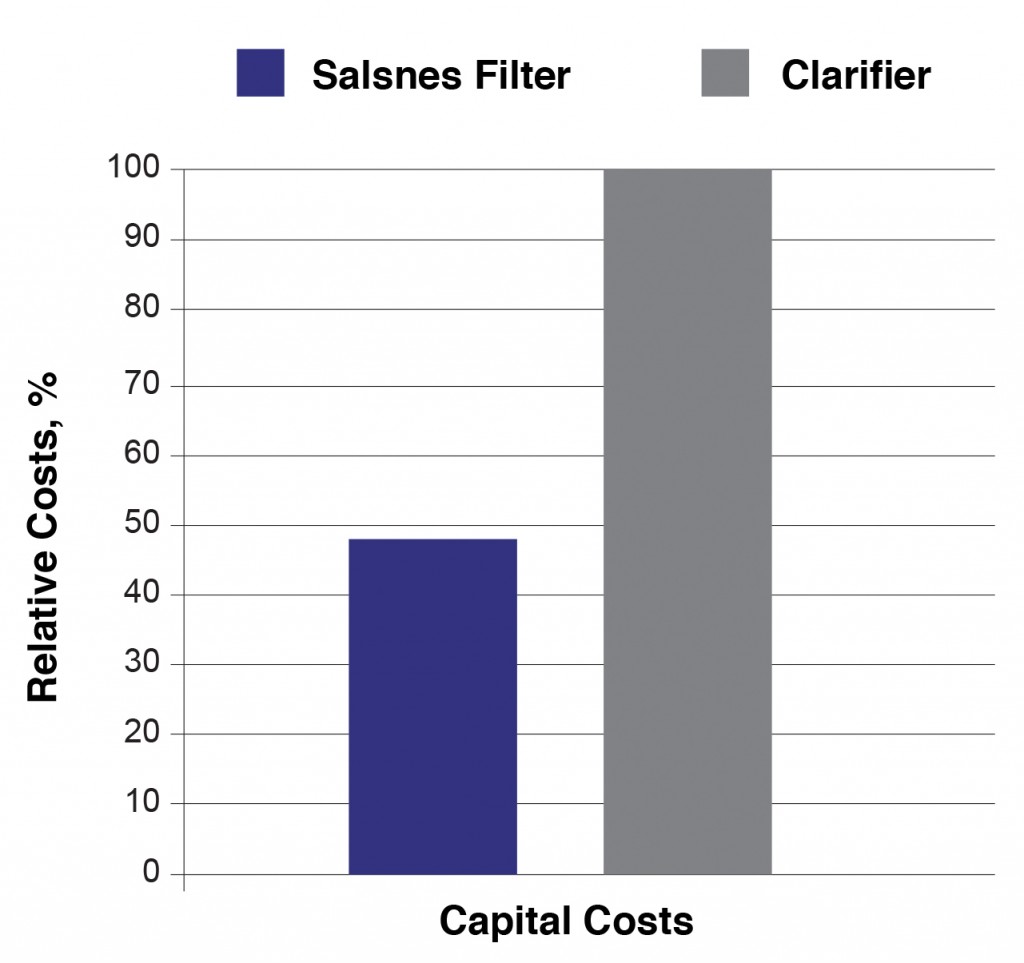

Cost efficiency

Salsnes Filter has a 30-60% lower investment and operating cost as compared to a conventional primary treatment system.*

* Graphic depicts an evaluation completed by the Norwegian State Pollution Control Agency to discover cost efficient technology that could fulfill the European Union’s stringent criteria for primary treatment. The savings for the Salsnes Filter are substantial. The system costs half that of conventional primary sedimentation and clarification.

Unlimited design flow capacity

The modular design of the Salsnes Filter system allows for installation configurations to serve any capacity requirement. Filters can perform together as one, sharing components such as the blower for the Air Knife filtermesh cleaning system.

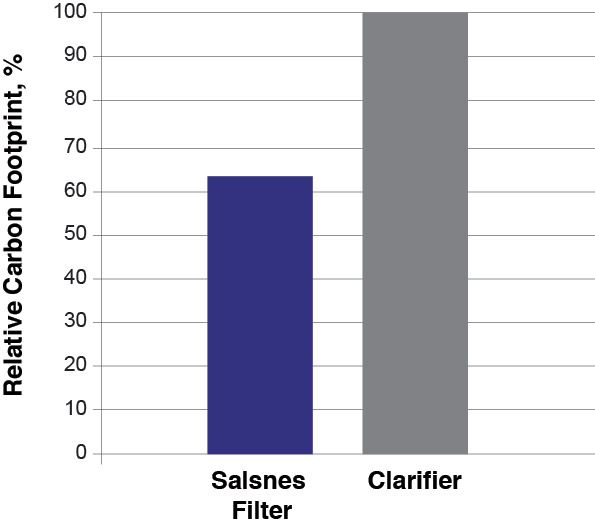

Environmental benefits of a small carbon footprint

This carbon footprint analysis compares the Salsnes Filter SF:6000 to a clarifier in a 2 MGD (315 m3/h) municipal wastewater treatment plant in North America. It reveals that the Salsnes Filter system has a substantially lower environmental impact mainly because less concrete is required for installation.

Reduce volume of sludge for disposal

For many wastewater treatment plants, sludge disposal is one of their larger expenses. This leaves many facilities looking for ways to reduce their total sludge costs. The sooner sludge is removed from the process, the more potential cost savings it can trigger in downstream processes.

The Salsnes Filter system is designed to quickly thicken and dewater with its integrated processes to produce the driest sludge possible. The sludge exiting a Salsnes Filter system is 20 – 30% dry matter (DM), while primary clarifier sludge can be 2% DM.