Aquaculture

Fish Hatcheries and Farms

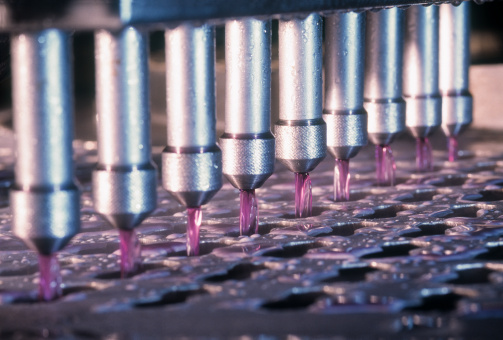

At fish hatcheries and farms, solids can develop in the water from fish waste and uneaten food. In high amounts, these solids negatively impact the growth and survival rates of the fish because they demand oxygen and contaminate the water with ammonia. A Salsnes Filter system can effectively remove these solids (without crushing like a typical drum filter) to maintain a high water quality for the fish.

Sea Lice

Sea lice are naturally occurring, minute parasites that attach themselves to the skins, fins and gills of fish. Infestation can occur anywhere; along coastlines, around fish farms, in vessels transporting live fish and at fish slaughterhouses. The most commonly used treatment methods only temporarily paralyze the sea lice, thereby allowing future infestations.

A Salsnes Filter system separates the sea lice (and their eggs) from the water to be properly disposed of. The almost 100% reduction in sea lice improves water recirculation, resulting in higher fish survival rates, and contributing to lower operational costs.

Slaughterhouses

The composition and strength of wastewater from slaughterhouses creates many treatment and discharge challenges for these facilities. It has high volumes of hard-to-filter components such as blood, dirt, manure and fat, oil and grease (FOG).

The composition and strength of wastewater from slaughterhouses creates many treatment and discharge challenges for these facilities. It has high volumes of hard-to-filter components such as blood, dirt, manure and fat, oil and grease (FOG).

The Salsnes Filter system can separate these components because of the design of the filtermesh. First, fiber and grain from manure are collected on the filtermesh. These larger particles begin to collect smaller particles to create a “filter mat”. Separation performance is enhanced as particles continue to build-up on the filter mat, creating progressively smaller holes that retain increasingly smaller particles.

Another important feature for slaughterhouses is the rate in which solids are separated to prevent proteins from biodegrading into dissolved ammonia and phosphorous. Less dissolved protein reduces the cost of biological treatment and produces less excess sludge to dewater.

Pulp & Paper

Water is used in nearly every step of the manufacturing process for a pulp and paper mill. So, of course these facilities have large volumes of wastewater to treat and sludge to dispose of. To save costs, many facilities would like to recover excess pulp fiber from their wastewater to be reused in the production line.

For those facilities not recovering fibers, our integrated thickening and dewatering processes are effective with fibrous material and can reduce the volume of sludge and associated disposal costs.

Read our White Paper for more information about the recovery and reuse of wood fibers in the manufacture of paper.

Tanneries

Tanning is one of the oldest industries in the world and produces some of the most challenging wastewater to treat and dispose of. Wastewater is highly toxic and can contain proteins, albumins, hair, blood, shavings, fat and grease. Water is used in many production processes creating high volumes of wastewater to manage. The Salsnes Filter system has unlimited design flow capacity, so installation configurations can be designed for high volumes of wastewater, even the chemically aggressive and high-loaded wastewater of a tannery.

Our advantage over other commonly used filters is that the system quickly and continuously removes TSS, COD and BOD in one compact unit without crushing solids into finer particles. No excess water for screen washing, costly chemicals for sludge conditioning or power for additional sludge dewatering equipment is required.

Food Processing

Wastewater generated from food processing facilities has characteristics that set it apart from other types of wastewater. Fruit and vegetable wastewater is nontoxic and biodegradable, but has very high concentrations of BOD and TSS. Wastewater in meat, poultry and fish processing facilities contain high amounts of fat, oil and grease (FOG). Some facilities require large volumes of high quality water.

The Salsnes Filter system can remove >50% TSS and >20% BOD. Removing high amounts of TSS and BOD in primary treatment can trigger cost savings in downstream processes. Fewer chemicals are needed for sludge conditioning, less power is needed for blowers in secondary treatment and there is less final sludge to dewater.

Whether a system is required for a new plant, or for retrofitting into existing facilities, a Salsnes Filter system fits because of its small footprint and versatile configuration options. Both water and filtered material can be recovered, or the integrated thickening and dewatering processes can reduce sludge volume for disposal.

Breweries and Wineries

The organic composition of brewery and winery wastewater is dominated by dissolved compounds which cause high biochemical and chemical oxygen demand (BOD, COD). But, the wastewater also contains solids, (e.g. Spent grains, spent yeast, fine colloidal solids and filtration aids like diatomic earth) which makes treatment more complicated.

Very often easy-settling solids like diatomic earth can collect on the bottom of anaerobic reactors and block diffusers. The Salsnes Filter system can remove >50% TSS prior to the anaerobic step to avoid this problem and to also avoid the use of additional filters or separators.