Reinforcing our joint Commitment to Advancing Wastewater Management

FILTEC has recently solidified its commitment to advancing wastewater management by securing an exclusive distribution agreement with Salsnes. This partnership marks a significant step forward for FILTEC in their mission to deliver the best in dewatering and reuse solutions to our Australian and New Zealand municipal and industrial customers.

Empowering Filtec Customers with Advanced Dewatering Technology

The exclusive distribution agreement between FILTEC and Salsnes provides Filtec customers with direct access to Salsnes’ advanced dewatering technology, spare parts, and associated equipment. This collaboration enhances integration processes and enables FILTEC to offer tailored reuse solutions that precisely meet the specific needs of our customers.

Salsnes – Pioneering Solids Separation Technology

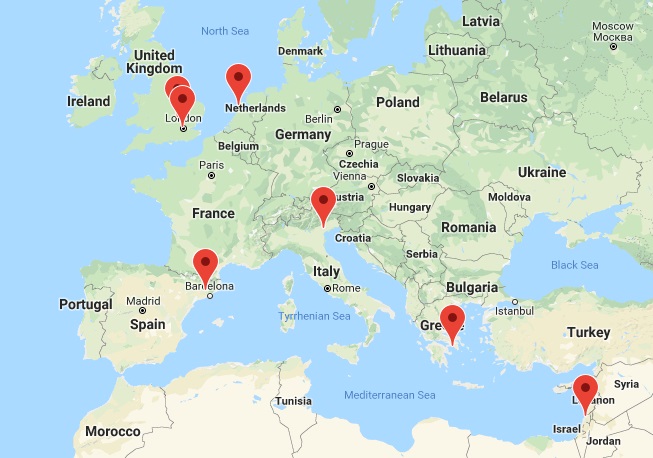

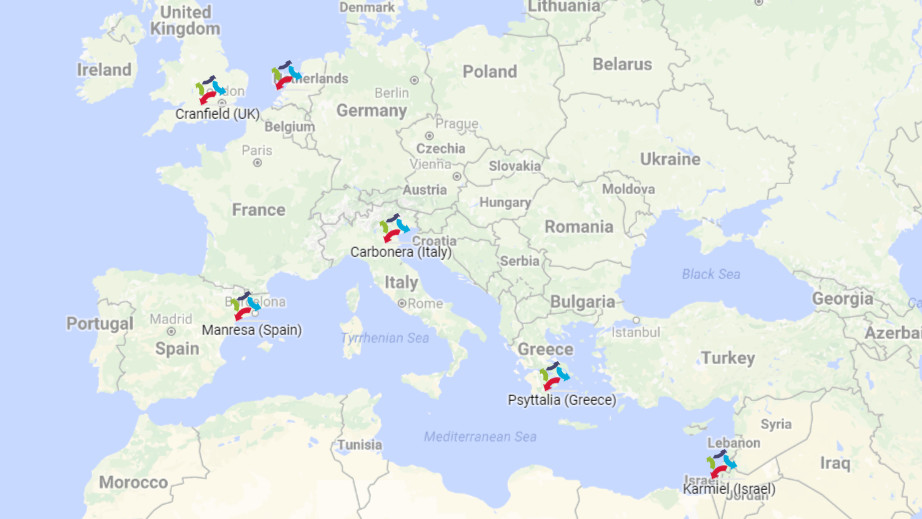

Salsnes has emerged as a leader in solids separation technology since its establishment in 1991. Through research and development efforts, Salsnes has crafted a highly efficient and dependable filtration system. With a global presence and a track record of successful installations, Salsnes Filter systems are recognised for their eco-efficient wastewater treatment solutions.

Benefits of Salsnes Filtration Systems

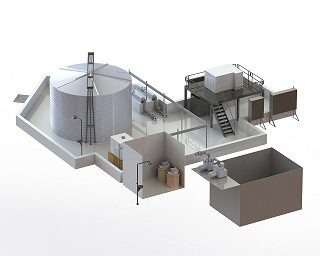

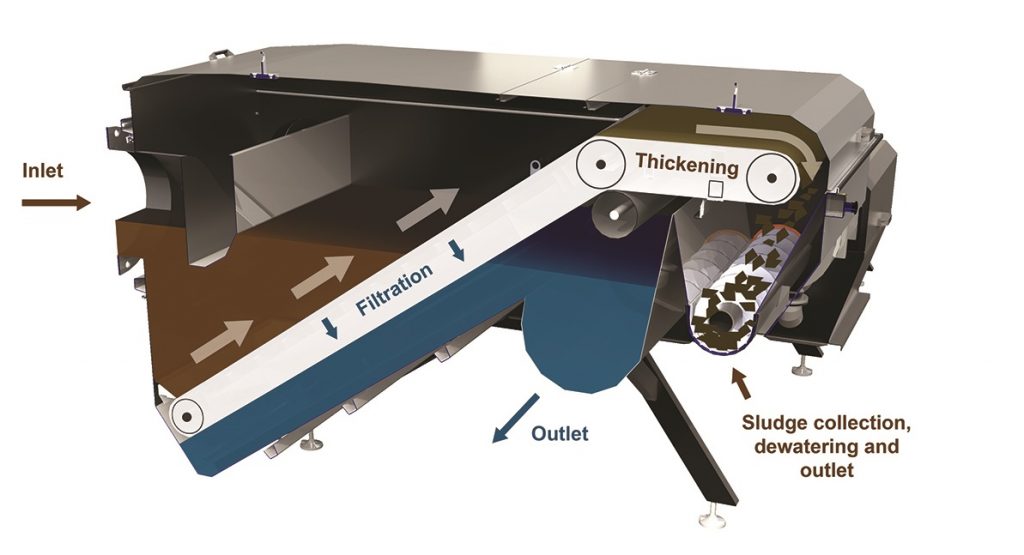

Compact Footprint

Salsnes Filter systems require significantly less land compared to conventional treatment systems, making them ideal suitable for urban areas and facilities with limited space constraints.

Cost Efficiency

Salsnes Filter systems are designed to reduce both initial investment and ongoing operating costs, helping customers streamline budgets while maintaining high standards of wastewater treatment.

In a Salsnes Filter system SOLIDS SEPARATION, SLUDGE THICKENING and DEWATERING are performed in one compact unit, removing, on average, 50% TSS, 20% BOD and producing drier sludge (20–30% DM)

Scalability

The modular design of Salsnes Filter systems ensures flexibility, allowing for seamless scalability to accommodate varying capacity requirements.

Environmental Benefits

Salsnes Filter systems prioritise sustainability throughout the treatment process, offering environmental benefits such as reduced carbon footprint and minimised sludge disposal costs.

FILTEC’s Track Record in Implementing Salsnes Technology

FILTEC has successfully deployed and supported Salsnes dewatering systems across multiple sites, including food processing plants, and industrial facilities in Australia and New Zealand. These installations showcase the effectiveness and reliability of Salsnes’ technology in addressing the unique challenges faced by different industries.

With ever-growing population, many wastewater treatment facilities face the need to increase treatment capacity but have limited or no space to install additional treatment equipment. A Salsnes Filter system is designed for situations such as this, using less than 10% the land of sedimentation tanks and clarifiers. By augmenting current primary systems with a Salsnes Filter system, wastewater treatment plants can increase treatment capacity using land they already have.

Setting New Benchmarks in Water Reuse and Dewatering Processes

As FILTEC strengthens its partnership with Salsnes, both companies remain committed to delivering innovative solutions that address the evolving wastewater treatment needs of customers in Australia and New Zealand. By leveraging Salsnes’ expertise and FILTEC’s industry experience, this collaboration aims to set new benchmarks in the areas of water reuse and efficient dewatering processes.