In the wastewater industry, new product innovation is at an all-time high. Companies are developing technologies that can greatly improve the efficiencies and environmental impact of municipal wastewater treatment. The SMART-Plant project was created to help find these innovative technologies and demonstrate their ability to recover resources, reduce energy demand and minimize carbon footprint.

The project was initiated by the Italian water utility Alto Trevigiano Servizi in cooperation with the University of Verona and the Veneto regional government. It has grown into a collaboration of 25 partners in ten countries including other universities, research companies, engineering firms, water utilities and manufacturers. Funding for the project comes from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 690323.

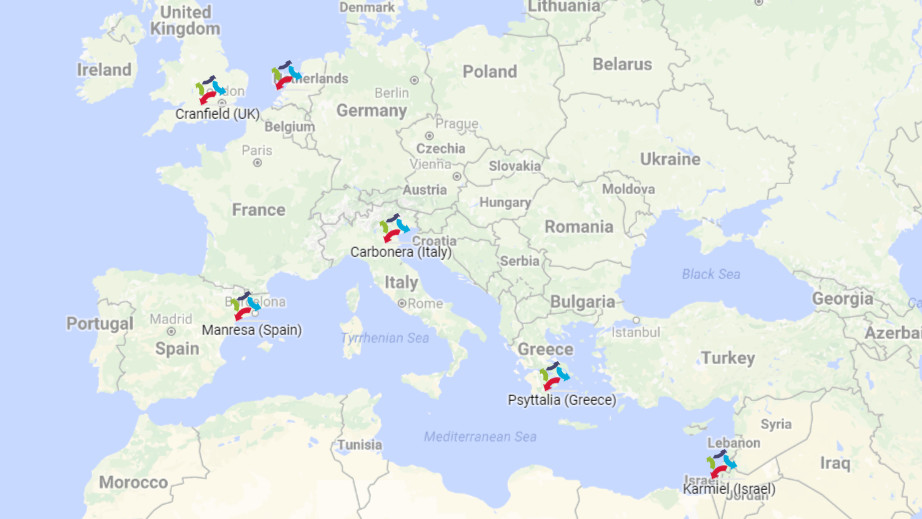

Six Wastewater Treatment Plants, located in The Netherlands, UK, Spain, Italy, Greece and Israel, are hosting nine pilot systems. These systems will operate for two years to monitor the performance of treatment technologies installed to recover biopolymers, cellulose and phosphorus from the wastewater to be processed into final commercial products.

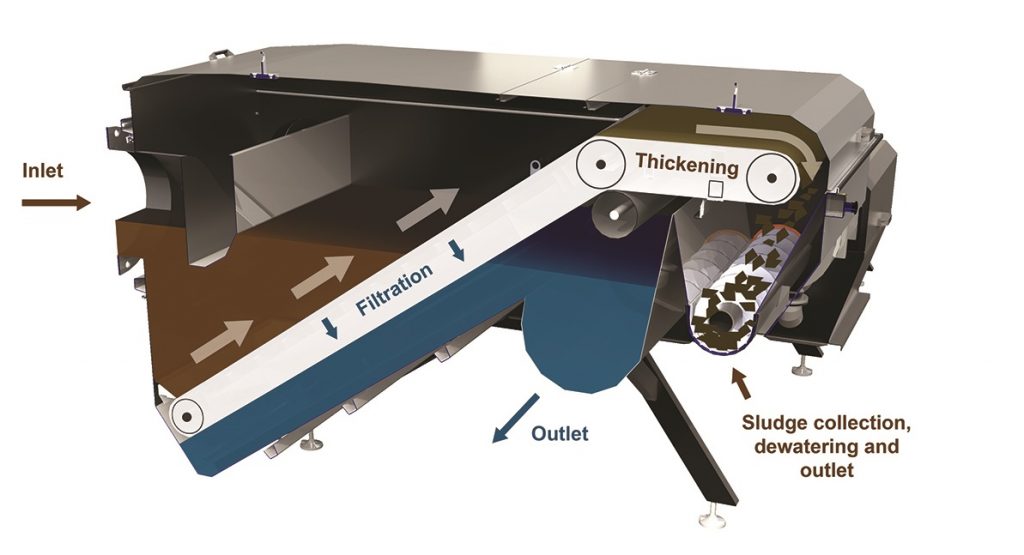

One of these pilot projects (called SMARTech 1) is taking place in Geestmerambacht, The Netherlands. Our Salsnes Filter system is currently being installed there to replace conventional primary sedimentation and perform primary cellulose harvesting. The system will separate fine cellulose fibers from toilet paper in the wastewater to produce a highly-concentrated sludge. For this pilot study, the sludge is then sent for post-processing inside the treatment plant. A compact sequence of equipment from the paper and food industries will treat the sludge to produce clean and marketable cellulose.

Some of the clean cellulose will be sent for further treatment at another SMART-Plant pilot system (called Downstream SMARTechA) to produce bio-composites.