Written by and originally posted by MAK Water:

Brewery Waste Water Treatment

Not satisfied with the existing waste water process, and faced with the possibility of trade waste license breaches, a trial for a Salsnes Fine Screen Filter was run.

A large food and beverage manufacturer approached MAK Water as they had increased production on multiple sites and their existing Waste Water Treatment Plants (WWTPs) were not keeping up with the new demand. They also wanted to eliminate the production of sludge as a by-product from the treatment process.

Not satisfied with existing waste water process, and faced with the possibility of future trade waste license breaches, the manufacturer engaged MAK Water to work collaboratively with their engineering consultant and run a pilot trial for a Salsnes Fine Screen Filter.

The trial ran for four weeks and was deemed a success, with the following results:

- Sludge dewatered to approximately 20% dry matter, eliminating the sludge from the current process and enabling the waste to be disposed of by a solids waste contractor

- Approximately 50% Total Suspended Solids (TSS) removal

- No additional chemicals were required to dewater the sludge in the filter.

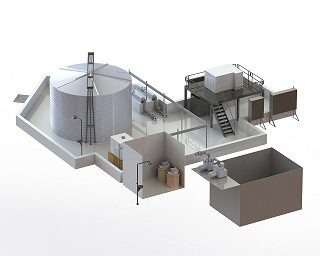

The food and beverage manufacturer went on to engage MAK Water to complete turnkey upgrades of their waste water treatment plants in both Victoria and NSW.

The scope included:

- Salsnes fine screen filters for solids reduction

- A pH correction system

- On site installation works

- Commissioning and operator training

Due for completion in November 2016, the upgrades are expected to reduce the client’s waste disposal costs and improve process control to eliminate any potential environmental license breaches.