Wastewater treatment plants are most commonly constructed and operated with the public unaware of the important work being done at these facilities. This status quo is likely to change in Hillerød, Denmark, where the Solrødgård Climate and Environmental Park is currently being constructed.

Public Space Merged with Public Utilities

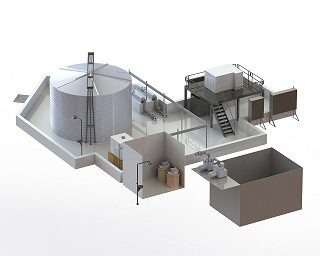

The 51-hectare Park, commissioned by the Danish utility consortium Hillerød Forsyning is using special architecture and design to merge a public recreational space with a wastewater treatment plant, as well as a recycling station and energy production plants.

This ultramodern park will be an attraction for local residents, and an educational tool for schools with its on-site Climate and Environmental Centre. The grounds will also have a large wetland area that will collect rainwater, as well as attract a rich bird population among other wildlife and plants.

Solrødgård Wastewater Treatment Plant

The Wastewater Treatment Plant is being constructed so that visitors can view the treatment technologies at work. Six Salsnes Filters are being installed at the facility, to treat wastewater for Hillerød Municipality.

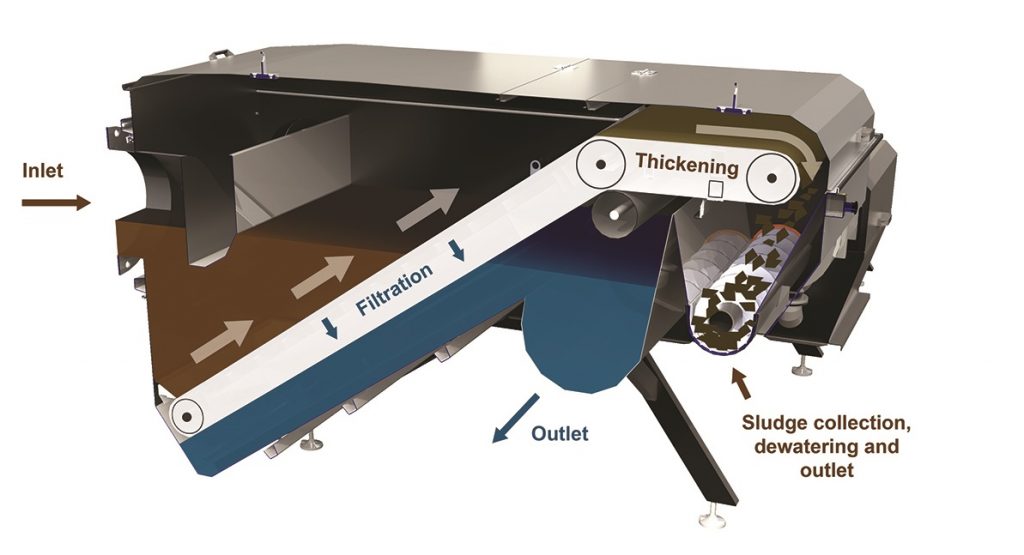

Primary Solids Separation and Sludge Thickening and Dewatering

The Salsnes Filter system will perform primary treatment, removing approximately 50% TSS from the wastewater, as well as thickening and dewatering sludge to approximately 6% total solids. This can be compared to conventional primary treatment which typically produces sludge with about 2% total solids. Having drier sludge means that no additional thickening processes are required before sludge can be further processed for use in biogas production.

Maximizing Biogas Production

Due to the speed of the filtration process, the fresh sludge taken from the filters ensures biogas production (and energy production) will be maximized. The design of the Salsnes Filter system allows control over the amount of organic matter that is separated in the primary stage, and how much is left in the wastewater for secondary biological treatment.

Further Reading:

- Licitationen Magazine Article (in Danish)

- Hillerød Forsyning Website – Images and construction updates